flexible PVC hose high speed braiding machine hydraulic hose making machine

PVC hose braiding machine

high speed braiding machine

flexible hose braiding machine

hydraulic hose making machine

BFB-200W series horizontal braider

Hose Braiding Machine

epdm tube braider

Main feature:

Fast braiding speed ,more suitable for rigid tube and big diameter tube.

Various active and passive methods such as noise absorbing, isolating, shocking absorbing material, etc.

Patented In house designed plate with guide, improve productivity and prolong machine life.

Machine stops & alarms when broken wire, out of wire out of tubing or rubber sheet detected, ensure machine runs safely.

CNC controlled, easy to adjust braid pitch (angle) & monitor status, data storage and safety protection.

Custom design available per request.

Specifications:

Greenland Benfa techology PVC hose braiding machine

Harness Braiding Machine,air conditioner hose braider,Hose Braiding Machine,epdm tube braider

Type |

carrier per deck |

carrier speed [RPM] |

braiding machine power |

haul off motor power |

braiding pitch set up |

carior tonsion |

braided hose OD |

| BFB16W-200CFS | 16 | 56rpm(max) | 4.0KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤16mm |

| BFB20W-200B | 20 | 45rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤20mm |

| BFB20W-200C | 20 | 45rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤20mm |

| BFB20W-200CF | 20 | 45rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤20mm |

| BFB20W-200CFS | 20 | 45rpm(max) | 5.5KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤20mm |

| BFB20W-200BCS | 20 | 45rpm(max) | 5.5KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤20mm |

| BFB24W-200C | 24 | 37rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤24mm |

| BFB24W-200CF | 24 | 37rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤24mm |

| BFB24W-200CFS | 24 | 37rpm(max) | 5.5KW2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤24mm |

| BFB24W-200Cs | 24 | 37rpm(max) | 5.5KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤24mm |

| BFB28W-200CF | 28 | 32rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤28mm |

| BFB28W-200CFS | 28 | 32rpm(max) | 5.5KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤28mm |

| BFB32W-200B | 32 | 26rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤32mm |

| BFB36W-200C | 36 | 26rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤36mm |

| BFB36W-200CF | 36 | 26rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤36mm |

| BFB36W-200CFs | 36 | 26rpm(max) | 5.5KW*2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤36mm |

| BFB36W-200A | 36 | 26rpm(max) | 5.5KW | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤36mm |

| BFB48W-200C | 48 | 19rpm(max) | 5.5KW2 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤55mm |

| BFB64W-200C | 64 | 14rpm(max) | 5.5KW*3 | 1.5KW | Electronic parameter set | 3.0kg—10.0kg | ≤140mm |

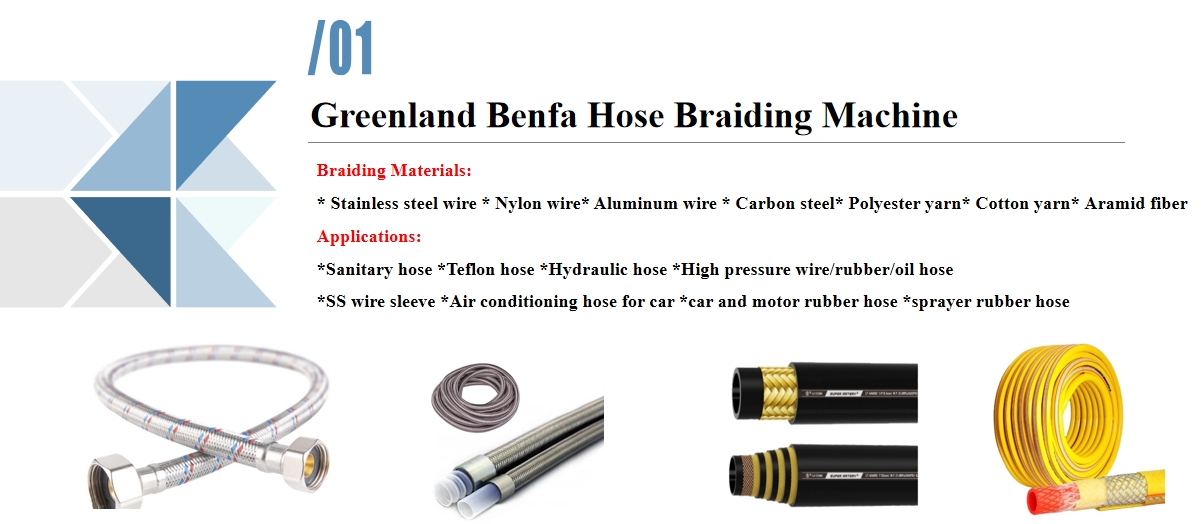

Applications:

Greenland Benfa techology hydraulic hose making machine

widely used in the manufacturing of steel wire braided high pressure rubber tube, steel wire braided sleeve, braided corrugated tube,

high strength wire braided tube. Big diameter cable brake hose ,air conditioner hose ,etc., suitable for the braiding material such as

stainless steel wire, steel wire ,alloy wire cotton yarn aramid yarn and other metallic wire and composite yarn .

Product Detail:

Greenland Benfa techology Harness Braiding Machine Air Conditioner Hose Braider epdm tube braider

details as below photos:

Description:

Greenland Benfa techology Harness Braiding Machine Air Conditioner Hose Braider epdm tube braider

200W:with horn gear OD200mm,suitable for bobbin OD ≤ 86mm

|

carriers per deck |

bobbin dimension |

|

8-96 |

80×28×277mm |

|

carrier speed [RPM] |

bobbin capacity |

|

20-55 |

130 cm3-360 cm3 |

The FB-200W series horizontal braider by Greenland Benfa Technology stands as an industry-leading solution, specifically engineered for the intricate

demands of soft and hard core big diameter high-strength EPDM tubes. This versatile machine finds wide application in the manufacturing sector,

playing a crucial role in producing various products such as steel wire braided high-pressure rubber tubes, steel wire braided sleeves,

braided corrugated tubes, and high-strength wire braided tubes.

Designed to cater to diverse industries, the FB-200W series excels in handling big diameter cable brake hoses, air conditioner hoses, and more.

Its adaptability extends to the choice of braiding materials, supporting the use of stainless steel wire, steel wire, alloy wire, cotton yarn, aramid yarn,

and other metallic wires and composite yarns. This broad material compatibility empowers manufacturers to choose the most suitable components

for their specific applications.

Key to the machine's performance is its exceptional braiding speed, making it particularly adept at handling rigid tubes and large-diameter applications.

This characteristic aligns with the industry's demand for efficiency, enabling manufacturers to meet production targets effectively while maintaining

high-quality standards.

The FB-200W series distinguishes itself through the incorporation of various active and passive methods for environmental management.

Utilizing noise-absorbing, isolating, and shock-absorbing materials enhances the overall working environment,

ensuring that the machine operates smoothly and without unnecessary disruptions.

An innovative feature is the patented in-house-designed plate with a guide. This unique design not only enhances productivity but also

contributes to prolonging the machine's operational life. It showcases Greenland Benfa's commitment to continuous improvement

and technological innovation in the field of harness braiding machines.

Safety is a top priority with the FB-200W series. The machine is equipped with an automated system that stops and sounds alarms in response to issues

like broken wires, depleted wire supplies, or the absence of tubing or rubber sheets. This ensures that the machine operates securely,

mitigating potential risks and maintaining a safe production environment.

The FB-200W series is CNC controlled, offering precision and ease of operation. This control mechanism facilitates the adjustment of braid pitch (angle)

and real-time monitoring of the machine's status. Additionally, the machine incorporates features for data storage and safety protection,

enhancing its overall efficiency and reliability.

Greenland Benfa Technology goes a step further by offering custom design options, acknowledging the diverse needs of manufacturers.

This flexibility allows clients to tailor the machine to their specific requirements, ensuring optimal performance in their unique production processes.

In conclusion, the FB-200W series horizontal braider is a comprehensive solution that redefines harness braiding technology. Its fast braiding speed,

material versatility, environmental considerations, patented design, safety features, CNC control, and customization options collectively position it

as a cornerstone in the manufacturing landscape. Greenland Benfa Technology continues to lead the industry by providing innovative and tailored

solutions for the production of air conditioner hoses, EPDM tubes, and other braided products.